Sustainable Transformer Technologies for an Evolving Grid

by Aleena Ahmad, Research Analyst – at Power Technology Research

- Renewable generation capacity of around 302 GW was installed globally in 2021 with 168 GW of renewable generation capacity coming from solar PV alone.

- Several technological solutions have emerged in the transformer industry over the years that play a supportive role in the transition to clean energy.

- According to Power Technology Research transformer suppliers that are offering innovative, sustainable and environment friendly transformer solutions are expected to increase their market share in coming years.

Since the landmark Paris Agreement (in 2015), economies across the globe have set ambitious renewable energy targets to combat climate change. These targets along with improved policies as per International Energy Agency have led to significant additions in the global renewable generation capacity especially in the developed countries over the years. Renewable generation capacity of around 302 GW was installed globally in 2021 with 168 GW of renewable generation capacity being solar PV alone.

These renewable capacity additions in turn require modernization and upgradation of the electricity grid in countries, creating demand for grid equipment especially transformers. Transformer industry on the other hand in response to the changing needs has been shifting to technological solutions that are sustainable and environment friendly that pair well with the renewables and aim for a cleaner grid as well.

Figure 1: Several Technological Solutions in the Transformer Industry.

Figure 1: Several Technological Solutions in the Transformer Industry.

Source: Power Technology Research

Several technological solutions have emerged in the transformer industry over the years that play a supportive role in the transition to clean energy. These technological solutions include sub-sea transformers, ester oil for transformers, green steel for transformers and digital transformers.

Sub-Sea transformer

Subsea transformer is a hermetically sealed, fluid filled, pressure compensated unit that is utilized for power supply operations in deep sea fields. The pressure compensating system of the subsea transformer maintains the internal pressure close to the pressure that is outside water by submerging the internals in liquid and removing all air and gas filled voids. The cooling of the transformer is carried out naturally through convection.

One of the applications of sub-sea transformers is the large open sea wind park installations which could use it to connect to the mainland grid. If a transformer is installed on the seabed, it eliminates the need to build a transformer specific floating platform. Other applications are tidal turbine parks and wave power converter parks.

Hitachi Energy recently began testing on the 24-MVA subsea transformer which will be supplied to OneSubsea. Currently, the evaluation of subsea transformer’s thermal behavior and pressure compensation system along with the reliability assessment in subsea conditions of the 55 T subsea transformer is underway.

Ester-oil

Generally mineral oil is used in transformers for insulation and cooling purposes, but ester oil provides a sustainable alternative to it which is biodegradable and reduces fire risk. A transformer specifically designed for use in solar parks with biodegradable fluids, low CO2 emissions and lesser material requirement during construction is being delivered and is expected to revolutionize the transformer industry. The transformer has been designed and developed by a collaboration between WESTRAFO,EUROLAM, Technology-DTV and the engineering division at EGP. It will be deployed in Spain as part of VIDCO solar cluster (under construction) that consists of three solar photovoltaic plants GEMINA, AGRIA and ALAUDAE.

The transformers are estimated to reduce emissions by 45 metric tons of CO2 and save 14 tons of raw material that includes iron, aluminum and insulating papers consumed during construction. Furthermore, the transformer uses ‘Natural Ester Cargill FR3’ which is soy-based blend with additives that reduces the leakage and fire risks usually associated with mineral oil and increases the ability of transformer to withstand high temperature.

Green steel

Green steel refers to the steel with the lowest carbon footprint which usually varies from producer to producer and is expected to evolve over time. Thyssenkrupp which is a market leader in electrical steel in Europe has introduced a steel with low carbon footprint and has set a precedent in industry for other manufacturers to opt for sustainable manufacturing processes. The new steel with low carbon footprint is expected to provide a significant push to the ongoing energy transition initiatives in the region. Fifty tons of this new electrical steel with reduced carbon footprint

has been procured by SGB-SMIT, which will use it to manufacture transformers for E.ON’s digital voltage substations in Germany. Keeping in mind the Eco-design Directive of EU which calls for the use of sustainable raw materials and products, it is expected that other utilities will also procure transformers built from green steel moving forward.

It is significant to note that electrical steel is used in the manufacturing of not just power and distribution transformers but in the charging columns of electric cars and electric motors as well. The use of green electrical steel in the manufacturing of these products will further the agenda of energy transition in the region as well as at the global level.

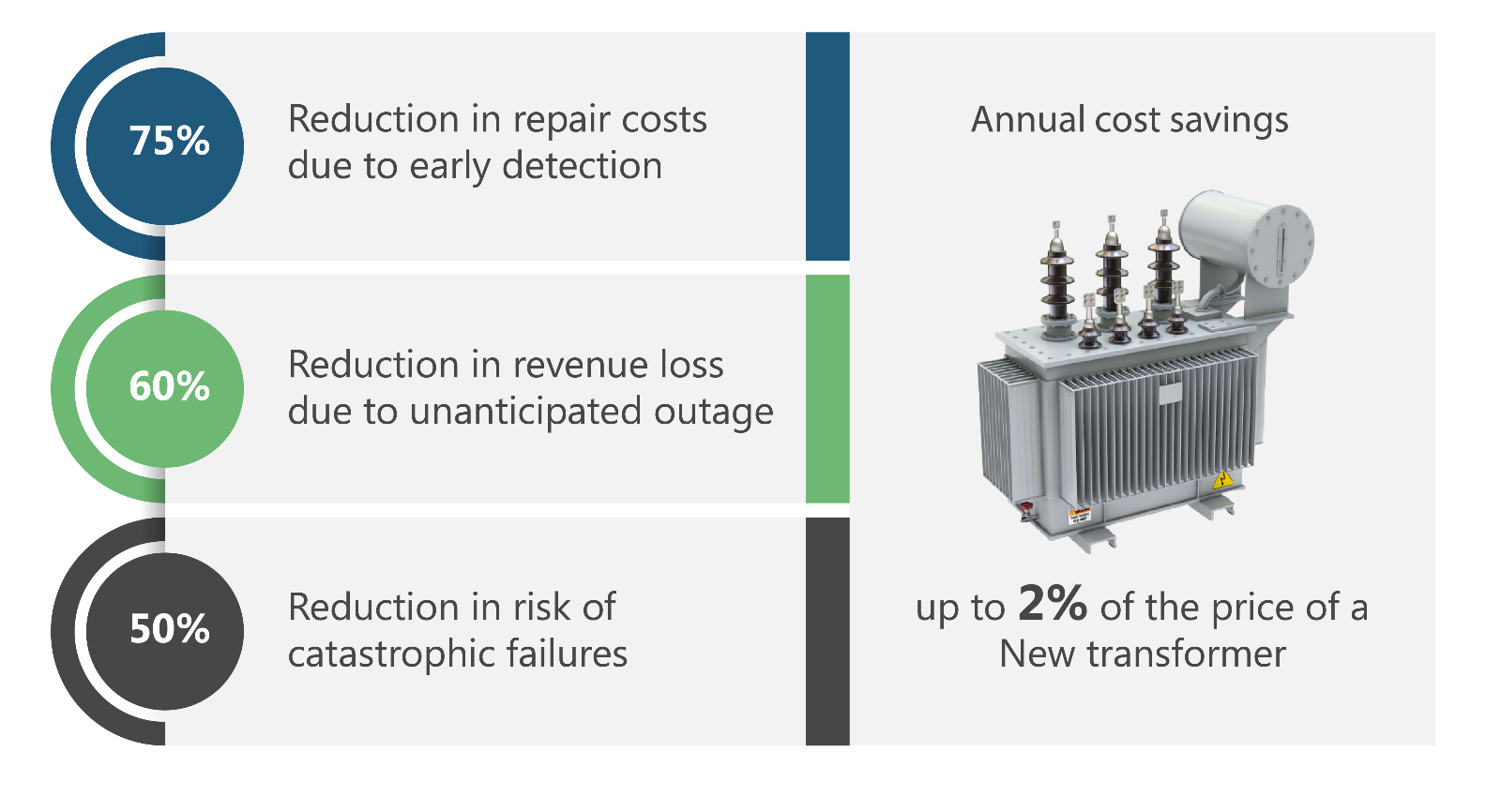

Figure 2: Potential Benefits of Transformer Digitalization. Source: CIGRÉ (Image is a property of Power Technology Research)

Figure 2: Potential Benefits of Transformer Digitalization. Source: CIGRÉ (Image is a property of Power Technology Research)

Digital transformers

Digital transformer is a transformer that is equipped with sensors that collect data to carry out asset management and grid optimization. Research published by CIGRÉ, a leading, global non-profit organization in the field of high-voltage electricity, found that transformer monitoring has the potential to deliver 75% reduction in repair costs due to early detection, 60% reduction in revenue loss due to unanticipated problems/outages, 50% reduction in risk of catastrophic failures and annual cost savings up to 2% of the price of a new transformer.

In 2020, ABB Power Grid supplied digitally enabled transformers to nine of Mainstream’s Chilean projects followed by provision of power transformers for 3 wind energy projects in Chile (Cuel, Sarco and Aurora) with a cumulative generation capacity of 332 MW. Last year Enel Infrastructure and Networks division opted to deploy the TXpertTM Ecosystem for digitalization of transformers from Hitachi ABB Power Grids.

Looking Ahead

According to Power Technology Research transformer suppliers that are offering innovative, sustainable and environment friendly transformer solutions are expected to increase their market share in coming years. Global energy transition can’t take place in isolation, the whole energy ecosystem needs to be supportive of the transition and that is where all these technologies have a huge role to play. Additionally, it is expected that the aging transformer installed base in the advanced economies especially that have the fiscal space, will be replaced with the latest transformer solutions that are more compatible with renewable generation applications specifically and energy transition in general.

Analyst Bio:

Market Analyst – Power Technology Research

Aleena Ahmad is a market analyst at Power Technology Research (PTR). She is involved in projects on the transformer topic at PTR and is responsible for data collection and analysis in various areas including the structure of distribution utilities, the installed base of T&D equipment, and future market trends. As a market analyst at PTR, she performs in depth analysis of the different technologies within the transformer market and their impact. Prior to joining PTR, Aleena worked at Nestle as an Electrical and Automation Engineer. Aleena comes from a technical background and has a BSc. in Electrical Engineering.

Contact:

Hassan Zaheer - Exec. Director Client Relations & Advisory

+49-89-12250950