Invited by the 2024 CWIEME Shanghai, Marcelo Hellmann, Chief Technology Officer at Hoyer Motors, delivered a speech on exploring efficient and sustainable induction motors in the green era.

Invited by the 2024 CWIEME Shanghai, Marcelo Hellmann, Chief Technology Officer at Hoyer Motors, delivered a speech on exploring efficient and sustainable induction motors in the green era. His presentation included an analysis of global electricity consumption, the advantages of permanent magnet motors (PM motors), and best practices from Hoyer Motors.

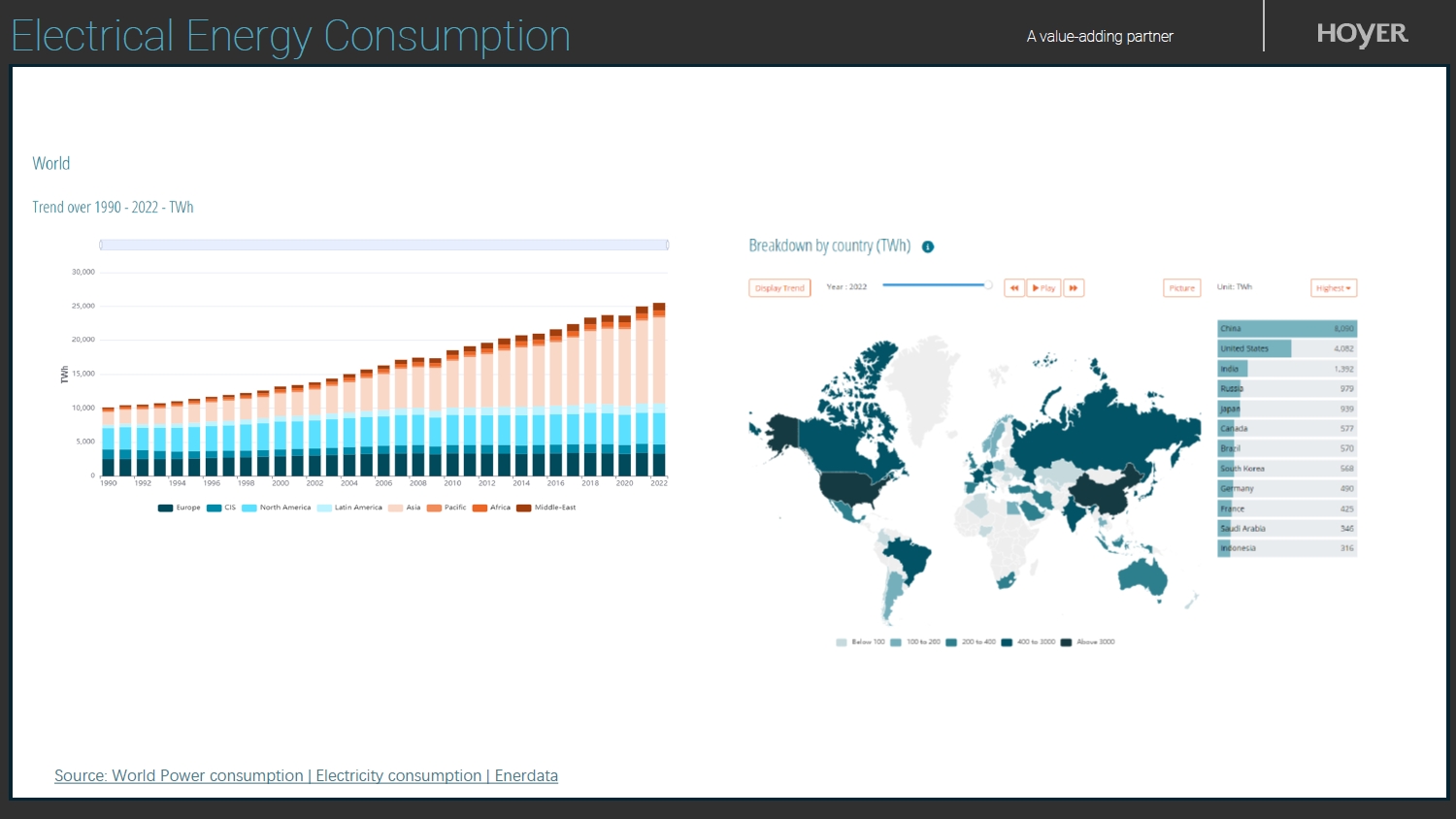

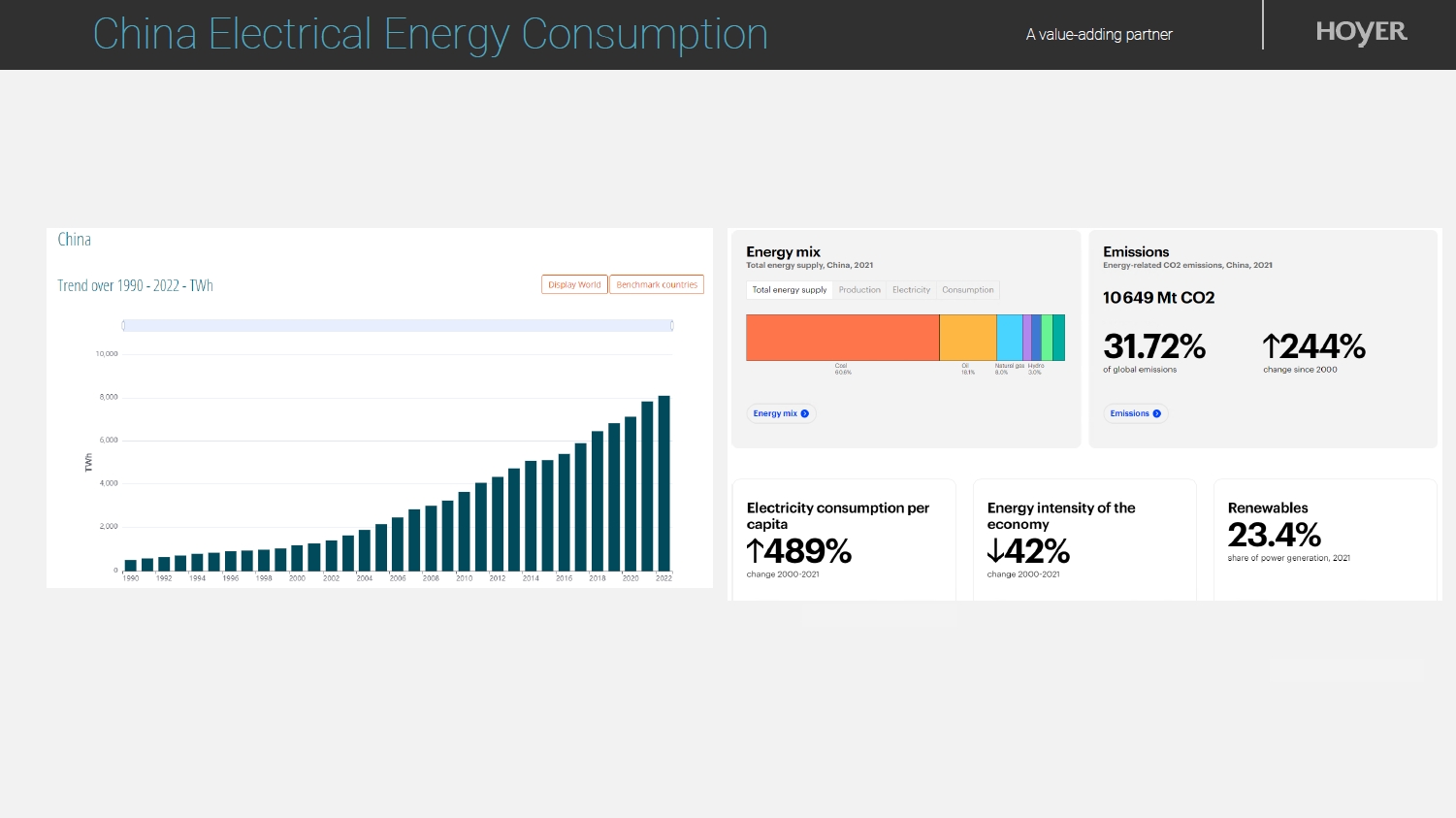

Regarding global electrical energy consumption, Marcelo pointed out that Asia has experienced the most significant growth from 1990 to 2022. A breakdown by country shows that China's electricity consumption has rapidly increased from 1990 to 2022, reaching a total of 8090 TWh in 2022, making it the highest consumer globally, followed by the United States. In terms of energy mix, China’s share of coal in 2021 was 60.6%, oil 18.1%, natural gas 8%, and hydro 3%. In terms of carbon emissions, China emitted 10649 Mt in 2021, accounting for 31.72% of global emissions—a 244% increase since 2000.

During his speech, Marcelo noted that 30% of global electrical energy is used by the industrial sector, and 65% of this is consumed by electric motors. Globally, electric motors account for up to 46% of all electrical consumption. To address this, Marcelo introduced permanent magnet motors, which can reduce energy consumption and improve efficiency, elaborating on their advantages.

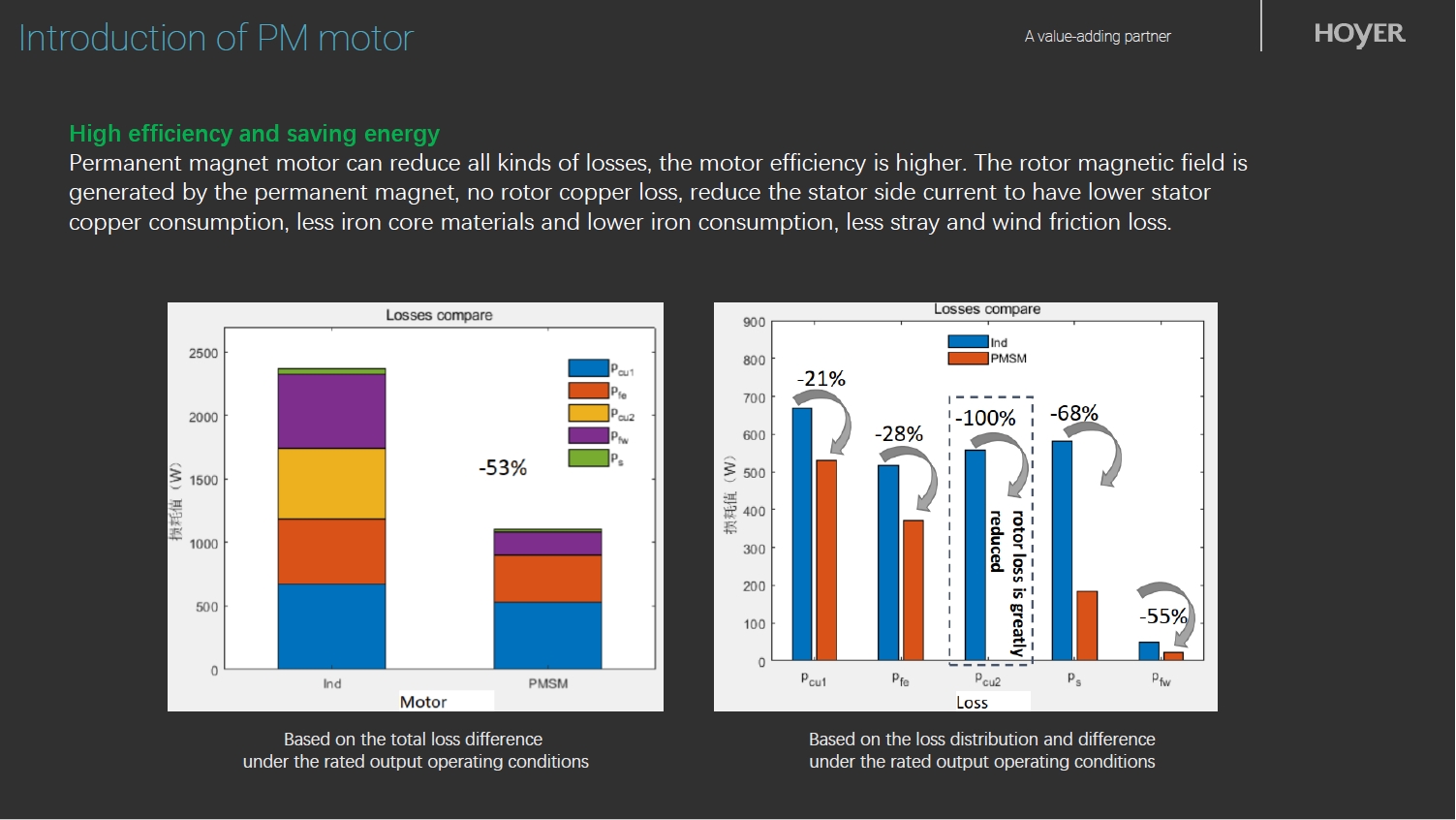

Permanent magnet motors can significantly reduce various losses, leading to higher motor efficiency. The rotor magnetic field is generated by the permanent magnet, eliminating rotor copper loss, which reduces the stator side current, leading to lower stator copper consumption, less iron core material usage, and reduced iron consumption, as well as less stray and wind friction loss.

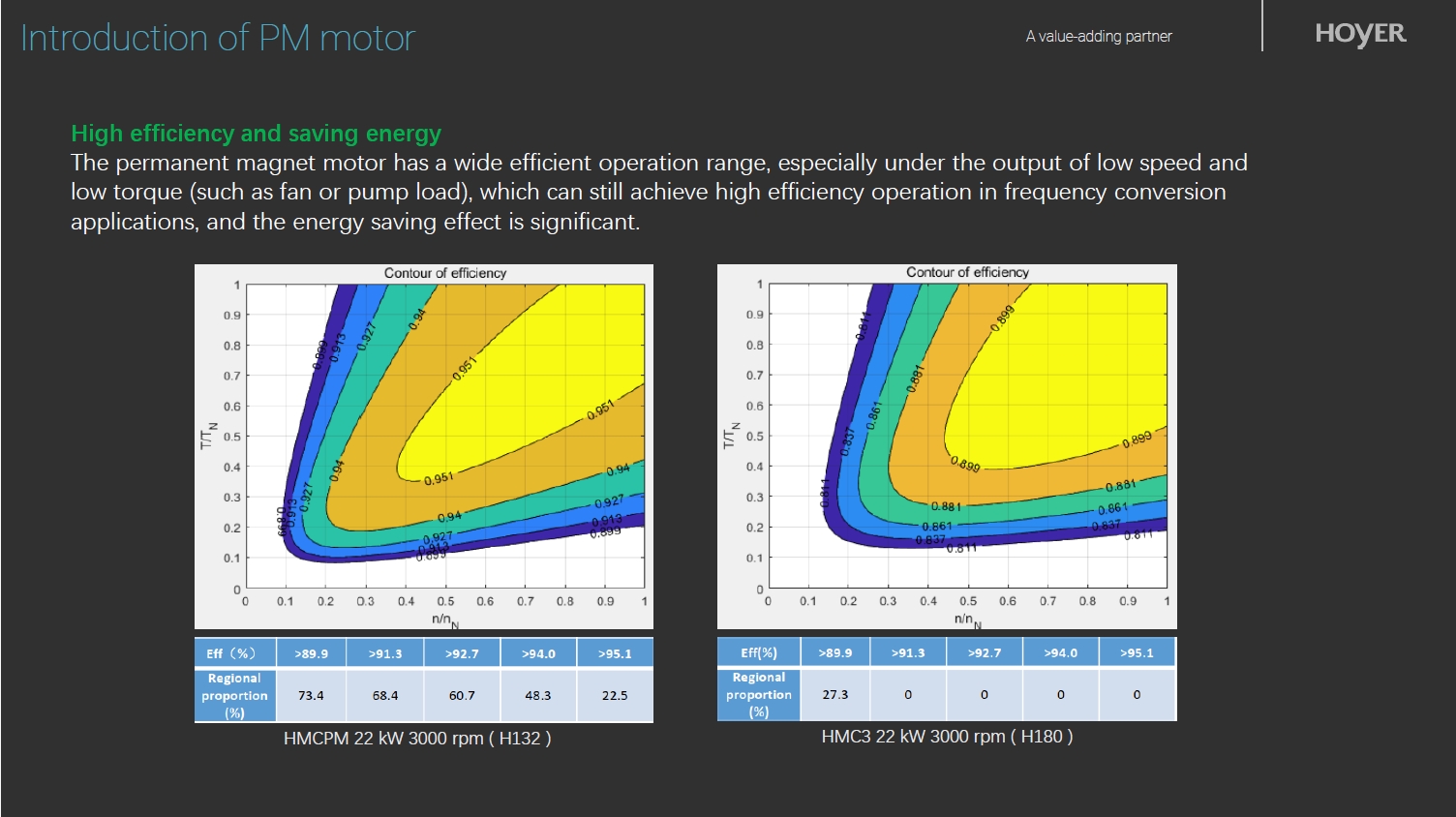

The permanent magnet motor has a broad efficient operation range, especially under low-speed and low-torque output (such as fan or pump loads), where it can still achieve high-efficiency operation in frequency conversion applications, resulting in significant energy savings.

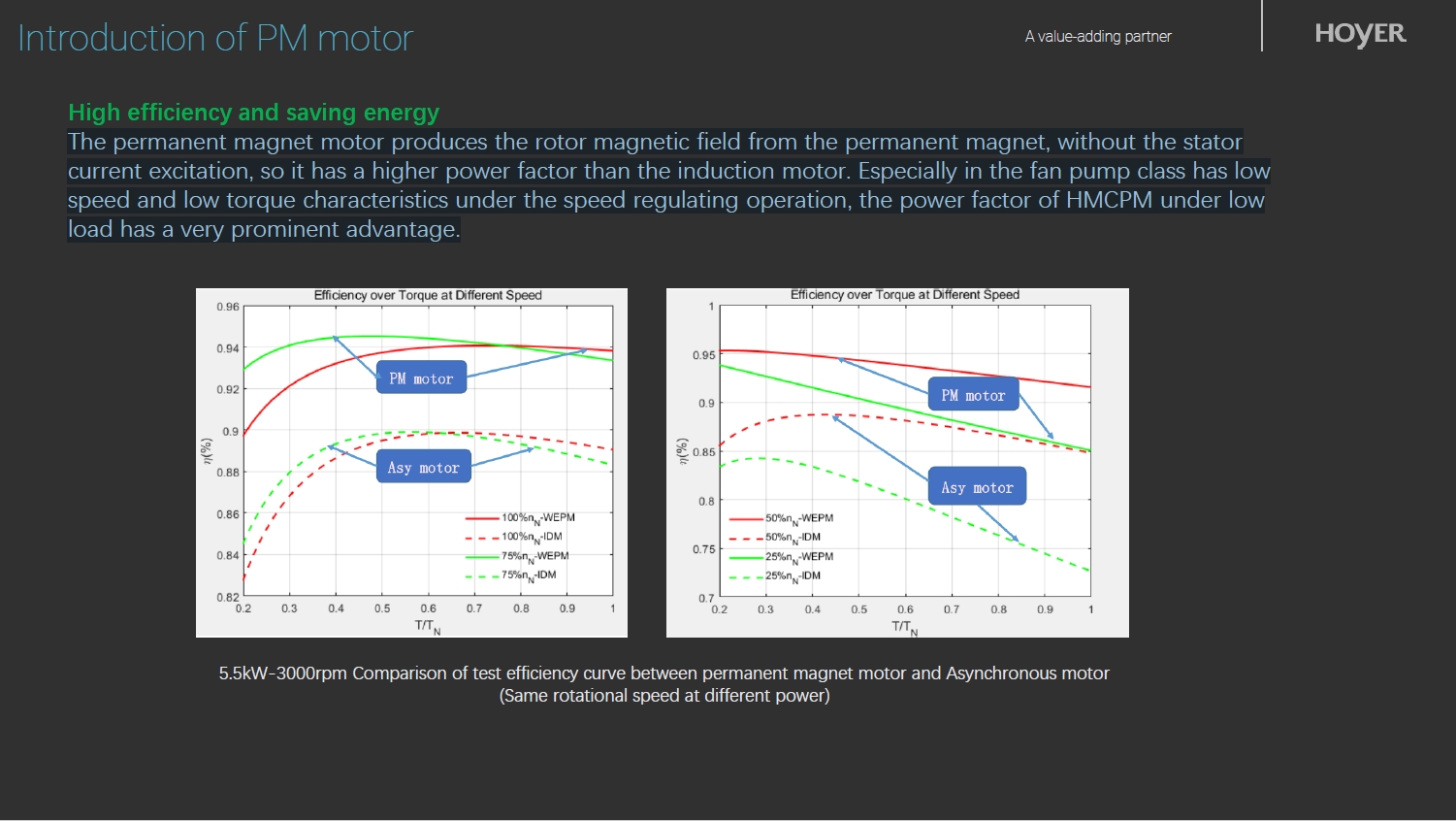

The permanent magnet motor produces the rotor magnetic field from the permanent magnet without the need for stator current excitation, giving it a higher power factor than an induction motor. This is particularly advantageous in fan and pump applications, where the power factor of HMCPM under low load has a very prominent advantage during speed-regulating operation.

Furthermore, Marcelo emphasized that regarding the electric motor life cycle, energy costs account for as much as 93.5% of the total cost, with acquisition costs at 2.5%, maintenance costs at 1.5%, and stoppage costs at 2.5%.