AI is enabling earlier fault detection, smarter maintenance and more flexible transformer operation. Learn how manufacturers and utilities are applying intelligence across the transformer lifecycle.

The transformer was once a passive component of the power system. Designed to step voltage up or down, it operated silently in the background of the grid. Today, that role is changing.

Transformers are becoming connected, data-rich assets. Sensors, analytics and artificial intelligence are turning them into intelligent equipment capable of monitoring their own condition, predicting failure and supporting operational decisions in real time. This is not a marginal upgrade. It marks a shift in how power equipment is designed, operated and maintained across the grid.

For manufacturers and utilities, the question is no longer whether AI will shape transformer operations, but how to adopt it in a way that delivers value while controlling risk. Data quality, integration with legacy assets, cybersecurity and workforce capability all sit alongside the technical opportunity.

This article explores how AI is influencing transformer design, manufacturing and operation, where the value is being realised today, and what OEMs and utilities need to consider as they plan the next phase of grid modernisation.

AI in transformer design and manufacturing

Transformer design has traditionally relied on deep expertise in electromagnetic theory, thermal behaviour and mechanical engineering. AI does not replace that knowledge, but it extends it.

Join us in Berlin to hear more about how drivers like AI are impacting the industry in real time

GET TICKETDigital twins and virtual prototyping

AI-enabled digital twins allow engineers to simulate transformer behaviour under real operating conditions before anything is built. Load profiles, temperature cycles, voltage stress and harmonics can all be modelled in a virtual environment.

Machine learning algorithms can run thousands of design variations in a short time, highlighting failure modes and performance trade-offs that would be difficult to uncover through manual iteration alone. The result is shorter development cycles, lower R&D cost and designs that are more closely aligned to specific grid requirements.

Generative design for cores and windings

Generative design tools apply AI to optimise core and winding geometry against defined constraints. Engineers can set limits on temperature rise, losses, material cost and size. The system then proposes configurations that balance these competing factors.

This approach is particularly relevant for renewable integration and power electronics-heavy environments, where loading patterns and harmonics differ from traditional grid operation. Instead of relying on standard designs, manufacturers can develop application-specific transformers with greater confidence.

Manufacturing quality and defect detection

On the factory floor, computer vision and deep learning are improving quality control. AI systems analyse images of core assembly, winding alignment and insulation processes to identify deviations in real time.

Catching defects before shipment reduces field failures, warranty exposure and rework. At scale, this improves yield and supports more consistent product quality across production lines.

Predictive maintenance and asset health

Maintenance strategies for transformers have long been based on fixed inspection intervals and conservative replacement timelines. While proven, this approach often leads to unnecessary maintenance on healthy assets and insufficient warning before failure on degraded ones.

AI supports a move from time-based to condition-based maintenance.

Early fault detection

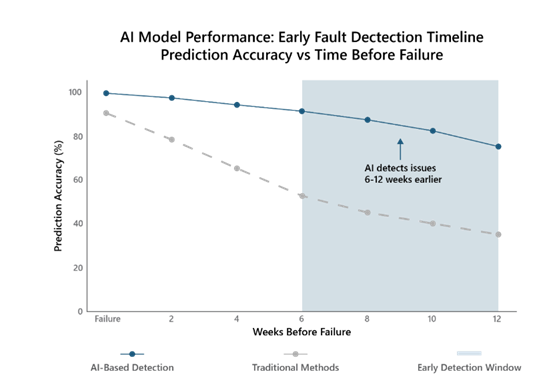

Modern transformers generate continuous data from dissolved gas analysis, partial discharge monitoring, temperature sensors, tap changer operation and oil quality measurements. AI models analyse this data to identify patterns that precede failure.

Unlike traditional rule-based interpretation methods, machine learning can recognise complex combinations of indicators and provide earlier alerts. In many cases, issues are identified weeks or months before conventional thresholds would be reached.

Figure 1: AI Model Performance: Early Fault Detection Timeline

Source: PTR analysis based on industry deployment data

Remaining useful life estimation

Estimating remaining useful life is one of the most valuable AI applications for asset managers. By tracking degradation trends in insulation, moisture and mechanical condition, models can forecast when intervention will be required.

This supports more informed capital planning, reduces emergency replacements and helps prioritise maintenance budgets across ageing fleets.

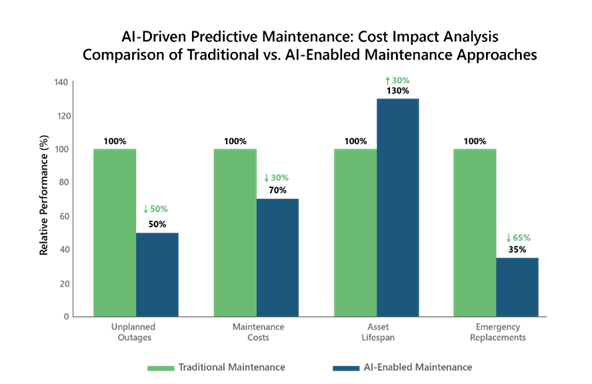

Impact on cost and reliability

Deployments across the sector show that predictive maintenance can significantly reduce unplanned outages and lower maintenance spend. For high-value power transformers with long replacement lead times, avoiding a single failure can justify the investment.

Beyond cost, improved asset health monitoring strengthens grid reliability during peak demand and extreme weather events.

Figure 2: AI-Driven Predictive Maintenance Cost Impact Analysis

Source: Industry studies and PTR analysis

Learn how trends are impacting cost and reliability in real time by claiming your free pass to CWIEME Berlin today

Secure your passOperational efficiency and dynamic management

Transformers operate in increasingly variable conditions. Electrification, distributed generation and changing load patterns place new demands on assets that were often designed for steady, predictable operation.

Dynamic loading and thermal ratings

AI models combine real-time load data with environmental inputs such as ambient temperature and cooling conditions to calculate dynamic thermal ratings. This allows transformers to operate safely beyond nameplate ratings when conditions allow.

For utilities, this provides additional flexibility during peak demand without immediate investment in new infrastructure.

Loss reduction and network optimisation

Across large distribution networks, AI can coordinate loading, tap changer settings and switching operations to minimise losses. While losses at individual units may appear small, the cumulative impact across thousands of transformers is significant.

Reducing losses lowers operating costs and supports decarbonisation goals through improved energy efficiency.

Managing renewable integration

Bidirectional power flows and voltage variability introduced by solar, wind and storage systems add complexity to transformer operation. AI systems help predict generation output, manage voltage regulation and support reactive power control.

This enables higher penetration of renewables while maintaining grid stability.

Managing risk in AI deployment

The benefits of AI come with new risks that must be addressed deliberately.

Cybersecurity and critical infrastructure

Connected transformers increase the attack surface of the grid. Sensors, communication networks and cloud analytics platforms all require protection.

Effective strategies include network segmentation, encrypted data transfer, access control and continuous monitoring. AI itself can also be used to detect abnormal behaviour that may indicate a cyber incident.

Data quality and model confidence

AI outputs are only as reliable as the data behind them. Inaccurate sensors, incomplete histories or inconsistent data formats undermine model performance.

Strong data governance, regular validation against physical inspections and continuous retraining are essential, particularly for safety-critical decisions.

Integration with legacy assets

Many transformers in service today were installed decades ago. Retrofitting sensors and connectivity can be complex and costly.

Most organisations adopt a phased approach, focusing first on critical assets and accepting that full fleet digitisation may not be practical in the short term.

Skills and organisational readiness

AI deployment requires capabilities beyond traditional electrical engineering. Data analytics, software integration and model interpretation are now part of asset management.

Cross-functional teams that combine domain expertise with digital skills are key to turning AI tools into operational value.

Figure 3: AI Implementation Roadmap for Transformer Operations

Source: PTR Inc.

A practical roadmap for OEMs and utilities

Successful adoption depends on structure and focus.-

Identify high-value use cases Start with assets and applications where failure risk, cost or capacity constraints are highest.

-

Build reliable data foundations Invest in sensors, secure data transmission and consistent data management practices.

-

Run focused pilots Define clear success metrics and validate performance across seasons and operating conditions.

-

Scale in phases Prioritise assets by criticality and integrate AI insights into existing operational systems.

-

Develop skills and partnerships Combine internal capability building with external technology and research collaboration.

-

Commit to continuous improvement Treat AI as an ongoing programme, not a one-off deployment.

Want more practical insights into how to cope with current challenges? Register for your free pass today.

Visit the showFrom equipment to intelligent infrastructure

AI is changing the role of the transformer. What was once a passive component is becoming an active participant in grid operation, able to report on its condition, support planning decisions and respond to changing conditions.

For OEMs, this shift opens new models built around intelligent products and digital services. For utilities, it offers a way to extract more value from existing assets while improving reliability and resilience.

The challenges are real, but they are manageable with disciplined execution and collaboration across the value chain. As electrification accelerates, intelligence is becoming part of the infrastructure itself.

The future transformer is not just smarter. It is designed, built and operated for a grid where data and decision-making are inseparable.

About the author

Rabbiya Shamsi

Senior Content Marketing Manager

PTR Inc.

Rabbiya leads content strategy across power grid, energy and e-mobility markets, supporting long-term positioning and growth for global clients.

Asad Tariq

Project Manager

PTR Inc.

About PTR Inc.

PTR Inc. is a strategic growth partner for the power grid and new energy sectors, supporting manufacturers and technology providers across electrical infrastructure, renewable energy and e-mobility.