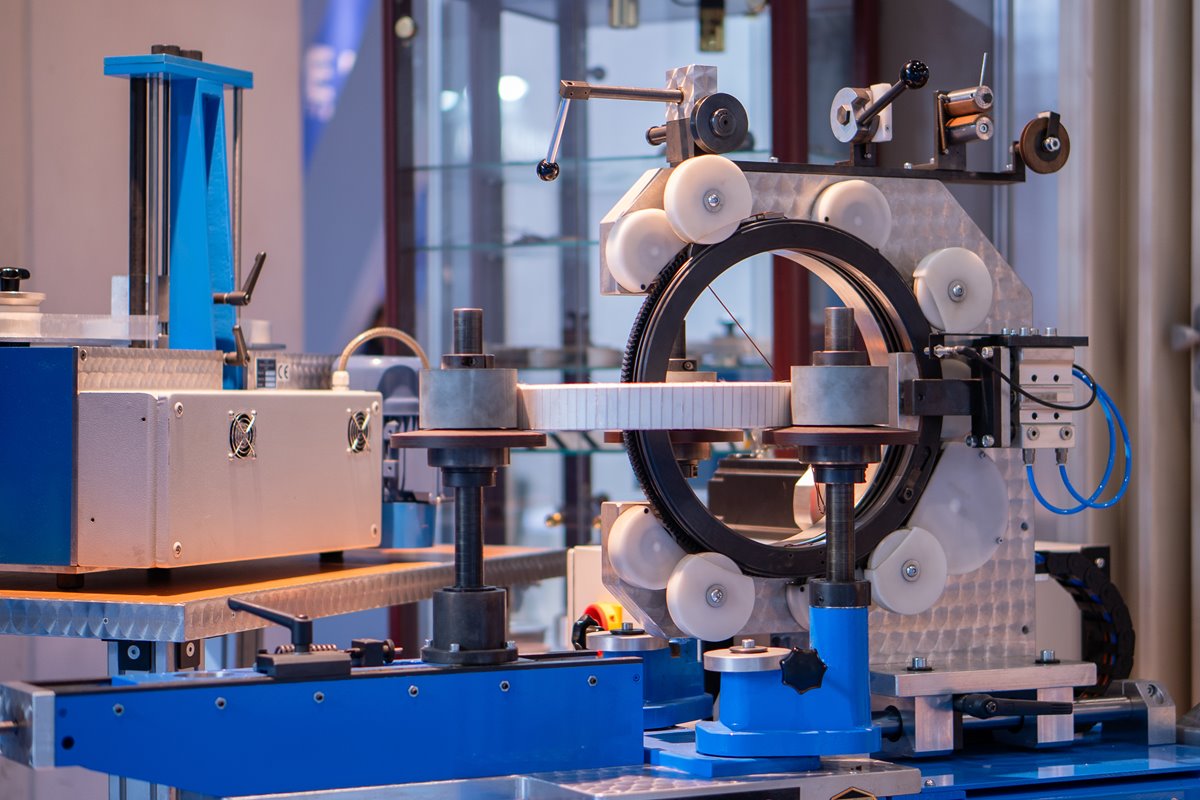

Electrical engineering and automation are transforming energy systems, industrial processes, and mobility. CWIEME Berlin is the leading global event for the coil winding, transformer, electric motor, generator, and e-mobility supply chain. This theme highlights the innovations shaping discussions and collaborations at the event, from advanced electric motors to cutting-edge automation in mechanical engineering.